The Essential Building Blocks of Reliable Production

Every industrial machine, from a simple conveyor belt to a complex multi-axis robotic cell, relies on fundamental components to move, sense, and control its operations. The ultimate reliability and efficiency of your entire production line depend directly on the quality, durability, and precise integration of these individual parts.

Our Industrial Machinery Components portfolio is specifically curated for machine builders (OEMs) and maintenance engineers who cannot afford compromise. We understand that in a demanding industrial setting, a single component failure means costly downtime and lost productivity. Therefore, we supply only rugged, industrial-grade components engineered to meet rigorous duty cycles.

Built for the Toughest Environments. Our components provide the necessary “muscle,” “nerve,” and “sense” for high-performance machinery, designed to withstand.

Extreme Conditions: Reliable operation despite exposure to dust, moisture, cutting oils, washdowns, and extreme temperature variations.

Continuous Stress: engineered to endure the high vibration, shock loads, and continuous 24/7 operation inherent in heavy manufacturing.

Precision Demands: delivering exact repeatability and high-dynamic response required by modern automated processes.

Whether you are building new machinery from scratch or retrofitting existing equipment for better performance, these components are the foundation of long-lasting, efficient operation.

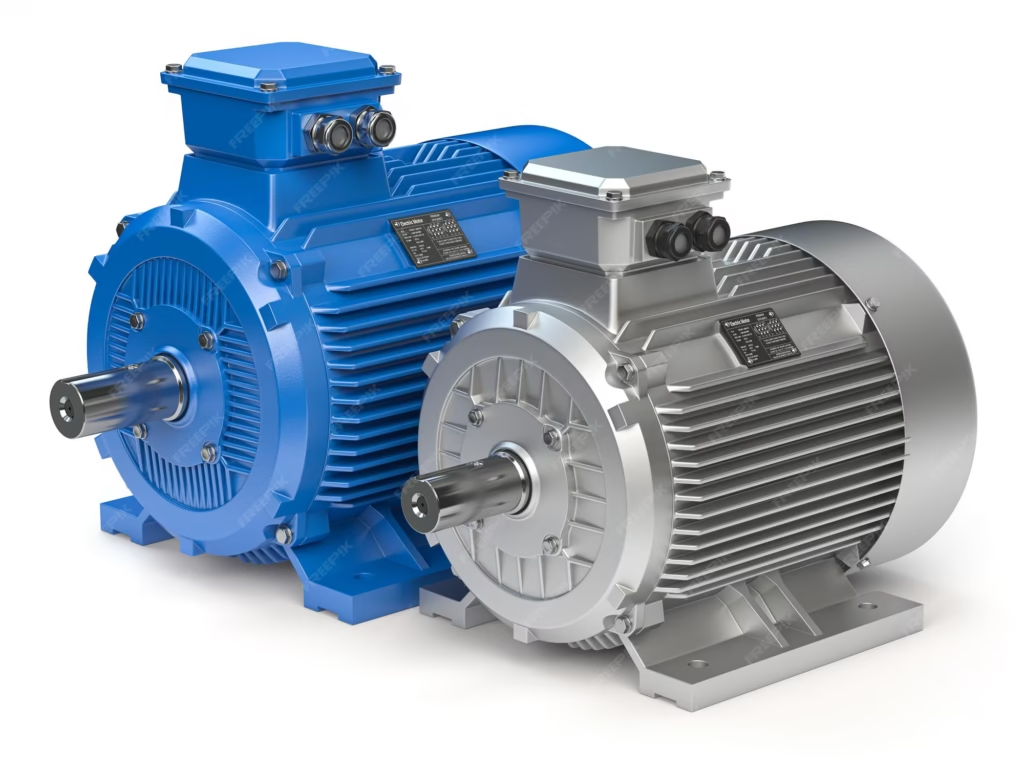

AC/DC Industrial Motors

The Robust Workhorses Driving Industrial Motion

Electric motors are the prime movers of industry, converting electrical energy into the mechanical motion that powers virtually every manufacturing process. We offer a comprehensive selection of both AC (Alternating Current) and DC (Direct Current) motors designed for heavy-duty applications. Our AC induction motors are legendary for their rugged simplicity and reliability in constant-speed applications like pumps and fans. Our DC motors are preferred for applications requiring high starting torque and precise speed regulation over a wide range.

Key Features & Benefits:

Robust Construction: Featuring cast iron or heavy-gauge steel frames and high-quality bearings designed to withstand mechanical stress and vibration.

High Efficiency: Premium efficiency ratings (e.g., IE3, IE4) to reduce energy consumption and lower operating costs over the motor’s lifespan.

Harsh Environment Ready: Available with high ingress protection ratings (e.g., IP55, TEFC – Totally Enclosed Fan Cooled) to operate reliably in dusty or wet conditions.

Versatile Options: Wide range of frame sizes, mounting configurations (foot, flange), and power ratings to suit any machine design.

Typical Applications:

Driving pumps, compressors, and industrial fans.

Powering conveyor belt systems and material handling equipment.

Heavy crushers, mills, and mixers in processing industries.

Servo Motors & Precision Drives

High-Dynamic Motion Control for Exacting Applications

When standard motor performance is not enough, and an application demands precise positioning, rapid acceleration, and exact speed control, Servo Systems are the answer. A servo system consists of a sophisticated motor with built-in feedback (encoder) and a matched precision drive that interprets commands from a controller. This closed-loop system allows for incredible accuracy and dynamic response, making them the standard for modern automation where speed and precision are paramount.

Key Features & Benefits:

Closed-Loop Precision: Integrated high-resolution encoders provide real-time feedback, ensuring the motor shaft is exactly where it needs to be, down to a fraction of a degree.

High Dynamic Response: Low inertia rotors allow for extremely fast acceleration and deceleration rates, maximizing machine cycle throughput.

High Power Density: Compact motor designs deliver exceptional torque relative to their size, ideal for space-constrained machinery.

Matched Systems: Motors and drives are optimized to work together, ensuring seamless integration and peak performance.

Typical Applications:

CNC machining centers and robotic arms.

High-speed packaging and labeling machines.

Automated pick-and-place systems and electronics assembly.

Pneumatic & Hydraulic Control Systems

Reliable Fluid Power for Automation and Heavy Lifting

Fluid power systems use pressurized fluids to generate force and motion. We offer solutions for both major branches:

Pneumatics (Compressed Air): Ideally suited for fast, clean, and repetitive low-to-medium force applications common in factory automation, such as clamping, gripping, and moving lightweight parts.

Hydraulics (Pressurized Oil): The solution of choice when immense force is required. Hydraulic systems offer high power density and are essential for heavy pressing, lifting, and bending operations.

Key Features & Benefits:

Pneumatic Components: Includes durable cylinders (actuators), fast-acting solenoid valves, and essential Air Preparation units (FRLs – Filter, Regulator, Lubricator) to ensure clean, reliable air supply.

Hydraulic Components: Heavy-duty hydraulic cylinders capable of multi-ton forces, robust directional control valves, and reliable power units designed for high-pressure operation.

Clean and Fast (Pneumatics): Ideal for food & beverage, packaging, and electronics manufacturing where cleanliness and speed are required.

High Force Density (Hydraulics): Provides massive force in a relatively small package for metal forming, pressing, and heavy material handling.

Typical Applications:

Pneumatic: Automated assembly jigs, packaging machines, pneumatic grippers on robot arms.

Hydraulic: Metal stamping presses, injection molding machines, heavy lifting tables.

Heavy-duty Sensors (Proximity, Laser, Level)

The Rugged “Eyes” of Industrial Machinery

In automated machinery, sensors are the crucial link between the physical world and the control system. They detect the presence of parts, measure distances, and monitor material levels. Unlike standard sensors, our heavy-duty range is engineered specifically for the factory floor. They are built with robust housings, reinforced electronics, and high IP ratings to ensure accurate readings despite exposure to cutting oils, dust, impact, and vibration.

Key Features & Benefits:

Proximity Sensors (Inductive & Capacitive): Reliable, non-contact detection of metallic and non-metallic objects. Essential for end-of-travel limits, part counting, and position verification.

Laser Distance Sensors: Utilizing laser time-of-flight or triangulation for highly accurate, long-range measurement of distance, thickness, or precise positioning of crane systems.

Level Sensors: Built to withstand corrosive liquids or dusty solids, providing reliable continuous or point-level monitoring in tanks, silos, and hoppers to prevent overflows or run-dry conditions.

Rugged Design: Metal or high-grade plastic housings with IP67/IP68 ratings for washdown environments.

Typical Applications:

Detecting the position of a product on a conveyor belt.

Measuring the level of liquids in chemical processing tanks.

Precise positioning of automated guided vehicles (AGVs) or crane hoists.